Technical consultation:

sales@drymixer.com

- 1. High Uniformity

- 2. Short mixing time,High Efficiency

- 3. 80% loading rate

- 4. Time saving,Energy saving,Space saving,Money saving.

- 5 Small damage to the original appearance of powders.

- 6. Solve the problem of ultra-fine powder mixing.

- 7. Solve the problem of light-heavy powder mixing.

- 8. Effectively solve the problem of uniform mixing diffuculty of trace elements

- 1. The important factor influenci

- 2. Particle size - an important

- 3. Powder fluidity is a double-edged sword

- 4. Pretreatment of powder mixture

- 5. Powder mixing principle introduce

- 6. Traditional powder mixers' adv

- 7. Selection of blending equipment

- 8. The basis of the uniform blending of powder

- 9. How to find the cause of mixing bad uniformity

- 10. Super light powder mixing precautions

- 11. Super fine powder mixing precautions

- 12. How to mix bad liquidity powder?

- 13. How to mix trace elements

- 14. A solution for powder's good

- 15. How does the dummy particles

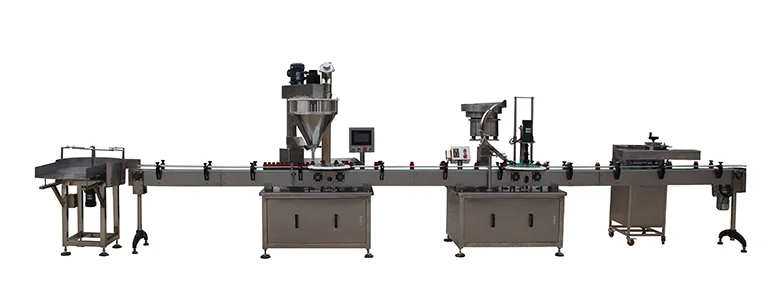

Bottle filling-Capper-Labbling-Coder packing line

JINHE New Factory Video: https://www.youtube.com/watch?v=rGOYaFf6Ot8

Powder filling machine: The machine adopts the combination of screw filling and electronic weighing feedback, and is controlled by microcomputer. It has functions of automatic quantitative, automatic filling, automatic correction error, counting and clearing. Suitable for compound seasonings, natural seasonings, food additives, flavors and fragrances, flour, milk powder, protein powder, solid beverages, sugar, pesticides, veterinary drugs, washing powder, enzyme preparations, feed additives, chemicals, new building materials, etc. , ultra fine powder), quantitative filling and packing of powder mixture.

Technical Parameter:

| Packing speed | 500-1500bottle/hour | Measuring range | 30-2000g |

| Power supply | AC380V 50Hz 0.9KW | Weight accuracy | ±3‰ |

| Machine size | (L)800×(W)800×(H)1960mm | Machine weight | 175KG |

Technical Parameter:

|

Applicable specifications : |

20-500ml |

|

Production capacity : |

30-50 bottles / min |

|

Filling accuracy: |

≤±1% |

|

Rotating (rolling) cover rate: |

≥98% |

|

Power supply: |

380V/50Hz |

|

Power : |

3 kw |

|

Weight: |

700Kg |

|

Dimensions: |

2500 × 1100 × 1600 (mm) |

Technical Parameter:

|

Number of screw bottle cap |

one cap |

|

Bottle cap size |

15-100mm |

|

Bottle diameter |

Φ35-Φ130mm |

|

Bottle height |

50-320mm |

|

Capping speed |

10-60bottles/min |

|

Rated power |

1kw |

|

Machine size |

150(L)*80(W)*160(H)mm |

|

Weight |

280kg |

|

Voltage |

220V,50/60hz,0.55kw |

Labeling machine:Put bottles into the conveyor belt, enter the separation mechanism, and after the separation mechanism separates these bottles, the bottle reaches the labeling position. The cylinder drives the soft silicone roller to clamp the bottle and drives it to rotate.In the appropriate time, the control system controls the corresponding motor to send the label and attach it to the position to be labeled, and is rotated and covered by the silicone roller. After the labeling is completed, the bottle is released and is continuously transported. The attaching action of a label is completed.

Technical Parameter:

|

Applicable bottle size |

Diameter:30-150mm; height:30-250mm |

|

Label length |

10-260mm |

|

Label width |

10-160mm |

|

Labeling speed |

0-60 bottles/min |

|

Applicable label |

Self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc. |

|

Label roll size |

Outer diameter<300mm; Inner diameter:76mm |

|

Machine size |

2200(L)*1400(W)*1750(H)mm |

|

Weight |

200kg |

|

Working air pressure |

4-8Kg/Cm2 |

|

Voltage |

220V,50/60hz,0.5kw |

Our Filling, Capping, packing and labeling Line including:

Bottle unscrambler,

Powder filling machine

Liquid filling machine

Capping machine

Sealing machine

Sticker Labeling machine

Shrink sleeve wrapping machine

Packing machine

Code printer machine

Certificates

Packing and Shipping

An experienced and well mannered sales and marketing team is committed to bringing you 100% customer satisfaction. In order to succeed in the rapidly changing podwer mixer market, our company has instituted a development policy that emphasizes "Serving the customer, improving products, providing best service,sureness and steadiness, devotion and dedication".Please feel free to contact us at any time.

DIASRIOUTION NETWORK

DIASRIOUTION NETWORK